The safety and efficacy of pharmaceutical products largely depend on controlling impurities in their formulations. Therefore, the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) has developed various guidelines, with the upcoming ICH Q3E guideline standing out. Specifically, this guideline focuses on assessing and controlling extractables and leachables (E&L) and aims to establish harmonized criteria to ensure patient safety.

This article explores the ICH Q3E guidelines, focusing on impurity identification, risk assessment, and best practices for regulatory compliance. We also highlight its connection with other ICH quality guidelines, such as the ICH Q3 impurity guidelines and ICH Q3D guidelines for elemental impurities.

ICH Q3 Quality Guidelines and the Role of Q3E

The ICH quality guidelines (denoted with the letter “Q”) ensure that medicines meet uniform global standards. Among these, the ICH Q3 guidelines have been crucial in regulating impurities in pharmaceutical products. These include:

- ICH Q3A(R2): Impurities in New Drug Substances

- ICH Q3B(R2): Impurities in New Drug Products

- ICH Q3C(R9): Guidelines for Residual Solvents

- ICH Q3D(R2): Guidelines for Elemental Impurities

- ICH Q3E: Guidelines for Extractables and Leachables

Previously, E&L issues were not comprehensively addressed due to the absence of a specific guideline. However, the ICH Q3E guideline for extractables and leachables, expected to be published in 2025, will provide a harmonized framework for assessing, testing, and controlling E&L in pharmaceuticals. As a result, this guideline fills a critical gap with standardized principles, aligning with other ICH Q3 quality guidelines.

Key Components of ICH Q3E: Impurity Identification and Risk Assessment

The ICH Q3E extractables and leachables guideline focuses on assessing and controlling substances that can migrate from contact materials (such as containers or delivery systems) into pharmaceutical products.

The key components of the guideline are:

- Identification of Extractables and Leachables in ICH Q3E Guidelines

The process begins with identifying E&L. On the one hand, extractables are compounds released from a material under stress conditions (such as high temperatures or solvent exposure). On the other hand, leachables are the compounds that migrate into the pharmaceutical product during use. Consequently, the guideline suggests adapting this process to different dosage forms and routes of administration.

- Risk Assessment in ICH Q3E Guideline for Extractables and Leachables

Once E&L are identified, a risk assessment must be conducted, considering factors like the route of administration and the drug’s indication. Furthermore, this assessment sets safety thresholds to determine when E&L levels are concerning. If necessary, toxicological studies or adjustments to the manufacturing process may be required.

- Reporting and Qualification Thresholds in ICH Q3E

The ICH Q3E guideline introduces harmonized thresholds for reporting and qualifying E&L. Moreover, these thresholds help standardize data interpretation and reduce variability in regulatory and industry practices.

- Implementing ICH Q3E: Best Practices for Compliance

Implementing the ICH Q3E is critical to ensuring the compliance and safety of pharmaceutical products. To achieve this, here are some best practices for meeting the guideline:

- Develop an E&L Study Plan Following ICH Q3E Guidelines

Organizations must design a specific study plan for E&L evaluation. This plan should define the type of studies required (extraction and migration), experimental conditions, and analytical methods. In this regard, a risk-based approach is recommended, adapting the study’s depth to the product’s characteristics.

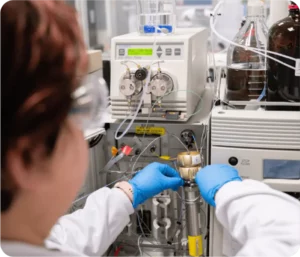

A crucial aspect of this evaluation is selecting robust analytical methodologies to accurately detect, identify, and quantify extractables and leachables. Several advanced techniques are commonly used, including:

- GC-MS (Gas Chromatography-Mass Spectrometry):

- Ideal for analyzing volatile and semi-volatile organic extractables.

- Offers high sensitivity and effectiveness in compound identification.

- Uses specific conditions for direct injection and headspace analysis to optimize extractable recovery.

- LC-UV/MS (Liquid Chromatography-Mass Spectrometry with UV Detection):

- Used for non-volatile organic extractables.

- Extractables are reconstituted in a mobile phase after being evaporated to dryness, preventing sensitivity issues caused by non-polar solvents.

- ICP-MS (Inductively Coupled Plasma Mass Spectrometry):

- Commonly used for detecting inorganic extractables, such as metals.

- Highly effective for identifying extractables in their elemental form.

The selection of the analytical method should be tailored to the material composition of the container closure system. It is also essential to assess mutagenic impurities, such as nitrosamines.

For a comprehensive evaluation, combining UPLC-HRMS, GC-MS/MS, and ICP-MS can enhance the detection of E&L in pharmaceutical products. These techniques cover a broad range of compounds with varying physical and chemical properties, providing a more thorough analysis.

Interdisciplinary Collaboration

The evaluation of E&L should involve experts from different areas, such as pharmaceutical quality, chemistry, manufacturing, and toxicology. Indeed, cross-department collaboration facilitates compliance with regulatory requirements and alignment with other international guidelines.

Define Clear Thresholds in Line with ICH Q3E Guidelines

Organizations must set clear thresholds for identifying, qualifying, and reporting E&L. These thresholds, aligned with ICH guidelines, help standardize practices and inform decisions about product safety. Additionally, they should be regularly reviewed and updated.

Documentation and Record-Keeping

Maintaining thorough documentation of studies, findings, and decisions is essential to comply with regulatory requirements. Not only does this aid audits, but it also ensures traceability of processes. Thus, it is important to include risk analyses and corrective actions taken.

Continuous Training and Updates

Staff should receive ongoing training on regulatory and scientific changes in E&L evaluation. For example, attending seminars and workshops on the subject helps maintain up-to-date knowledge and fosters a quality-driven culture within the organization.

Post-Commercialization Monitoring Aligned with ICH Q3E

The implementation of ICH Q3E does not end with product approval. It is vital to establish procedures for post-commercialization monitoring, including additional E&L studies and monitoring adverse effects related to impurities. This ensures that patient safety remains a priority.

The ICH Q3E guideline for extractables and leachables (E&I) is a critical step toward global standardization in impurity evaluation, complementing other ICH quality guidelines like the ICH Q3D guidelines for elemental impurities and the ICH Q3C guidelines for residual solvents.

At AMSbiopharma, we specialize in E&L analysis, providing advanced services to ensure your products meet the most demanding regulatory standards. To this end, we use cutting-edge techniques such as UPLC-HRMS, GC-MS/MS, and ICP-MS to ensure precision and scientific rigor in our work.

Need to ensure compliance with the ICH Q3E and guarantee your products’ quality?

Contact us and find out how we can help!

References

International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). Q3E Concept Paper [Internet]. Geneva: ICH; (s.f.) [cited 2025 March 07]. Available from: https://www.ich.org/page/quality-guidelines.

International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). Quality Guidelines [Internet]. Geneva: ICH; (s.f.) [cited 2025 March 07]. Available from: https://www.ich.org/page/quality-guidelines.

Moyer KL, Scull JR, Ruberto M. Extractables and leachables. In: Specification of Drug Substances and Products. Elsevier; 2020;535-557. doi: 10.1016/B978-0-08-102824-7.00020-8

Ramamoorthy, S., Chong, NS, Hotha, KK. Strengthening Extractable & Leachable Study Submissions: Best Practices to Avoid Regulatory Deficiencies. American Journal of Analytical Chemistry. 2024;15:368-394. doi: org/10.4236/ajac.2024.1512025.